| Sign In | Join Free | My uabig.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My uabig.com |

|

Brand Name : AllWin

Model Number : HZPLUS50

Certification : ISO9001

Place of Origin : China

MOQ : 1-5sets

Price : USD28500-38500/set

Payment Terms : T/T, MoneyGram, Western Union

Supply Ability : 30sets /month

Delivery Time : 20-30 Working Days

Packaging Details : Wooden boxes

Inner cylinder material : SIC Ceramic

Power : 37KW

Voltage : 380V and 460V

Litre : 50Litre

Disperser's material : Ceramic or stainless coated PU

Fineness : 300-500nm

grinding type : Compound Disc Pin

Grinding beads : 0.3-0.4mm

Higher Capacity And Save Energy HZPLUS50 Horizontal Bead Mill For MLCC Print Ink Nano Meter Materials LFP

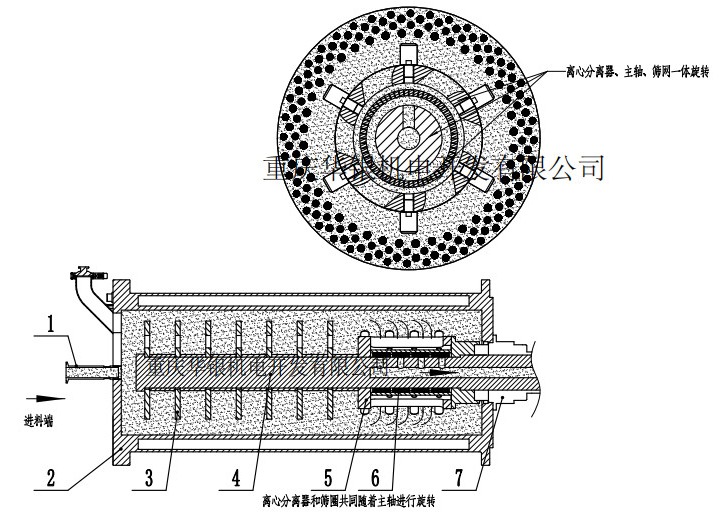

HZPLUS series is Compound Disc Pin structure with Dynamic discharge( Axis discharge), could meet all kinds of micron fineness griding,, widely used in paints coating, chemical fiber,food,cosmetic and namo materials industry. this series are general structure with flow discharge, super wearable materials for micron fineness demands.

The main introduction of Bead Mill

1. The compact and stable structure : the motor is placed on the upper part, the grinding chamble is placed on the lower part, and the total height of the equipment is low. More than 20L large model sander with cylinder slide rail for easy maintenance.

2. Double end mechanical seal: It has 2 patented technologies, with forced coolant, sealing ring resistant to 1600 kinds of solvents, coolant is compatible with materials, no pollutants, reliable operation.

3. Discharging separation system :Large flow, nonclogging: dynamic hollow rotor-super large area slot cylinder separator uses dynamic centrifugal force separation principle.Use of extremely small grinding beads ( 0.3 to 3 mm).No export blockage occurs under high flow conditions. Good heat dissipation, narrowest particle size distribution.

4. Grinding inner chamble : It has two patented technologies: chamble cooling and disassembly. The chamber volume is from 0.6-300L. The materials are stainless steel, alloy steel, ceramic, hard alloy, polyurethane, etc.

The Main parameter

1.The explosiong-proof motor:37kW

2.Effective volume of grinding chamberL: 50L

3.Water pressure Mpa:0.3

4.Cooling water consumption:2.0-2.5L/min( Advise offer the cooling water less10°C)

5.Dimension:1900*1200*2000mm

6.Weight:1500kg

The Main instructions of HZPLUS50

| NO | Items | HZ PLUS50 | Notes | |

| 1. | Core technologies | Mechanical sealing | Intelligent double mechanical | Allwin technology |

| Inner Chamber | Silicon Ceramic | Super wearable | ||

| Grinding system | SUS304 stainless steel | Disc type | ||

| Static discharge screen ring | Dynamic rotation and SUS304 Screen | |||

| 2. | Feeding and discharging end covers on the Chamber | 304 stainless steel | Easy Clean | |

| 3. | Bearing | NSK Bearing | ||

| 4. | Feed pump | 1” Pneumatic diaphragm pump with Buffer tank | ||

| 5. | Outer chamber | 304 stainless steel | ||

| 6. | Dispersing shaft | 40Cr with hard chromium plating | ||

| 7. | Electrical appliances | Motor | 37kW Ex-proof | Brand:Pinxing or Wannan |

| Safety protection system | Material temperature, chamber pressure, sealing liquid level, sealing liquid pressure | |||

| Electrical components | Electrical box, pressure gauge, thermometer, solenoid valve, winding pipe with EX-proof | |||

| Light alarm system | with | |||

| Electrical brand | Delixi | |||

| 8. | Cooling water pipeline | Hose+ Hard tube | ||

| 9. | Trace slide | 1 sets for free | ||

Pictures of Customers visit our plant

The Package of wooden boxes:

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24 hours feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

Note:

1.We will recommend the suitable bead mills according to your information and demand, such as industry, fineness, temperature, viscosity,production capacity etcs.

2. The Materials of inner chamber and Dispersing disks can be chosed according to your different grinding materials and industries.

3. The control system will be matching of different demand, such as PLC or traditional Button type.

If need more detailed information and Price, please don't hesitate contact us, Also Warmly welcome to visit us.

|

|

Save Energy Horizontal Bead Mill For MLCC Print Ink Nano Meter Materials LFP Images |